So it turns out the metal coolant plate under the stock intake isn’t a very good design. it’s a dissimilar metal from The Aluminum Intake and it looks like it’s Stamped Out of sheet metal and coated in zinc. I cleaned mine since it was super corroded and thought I could reuse it but apparently […]

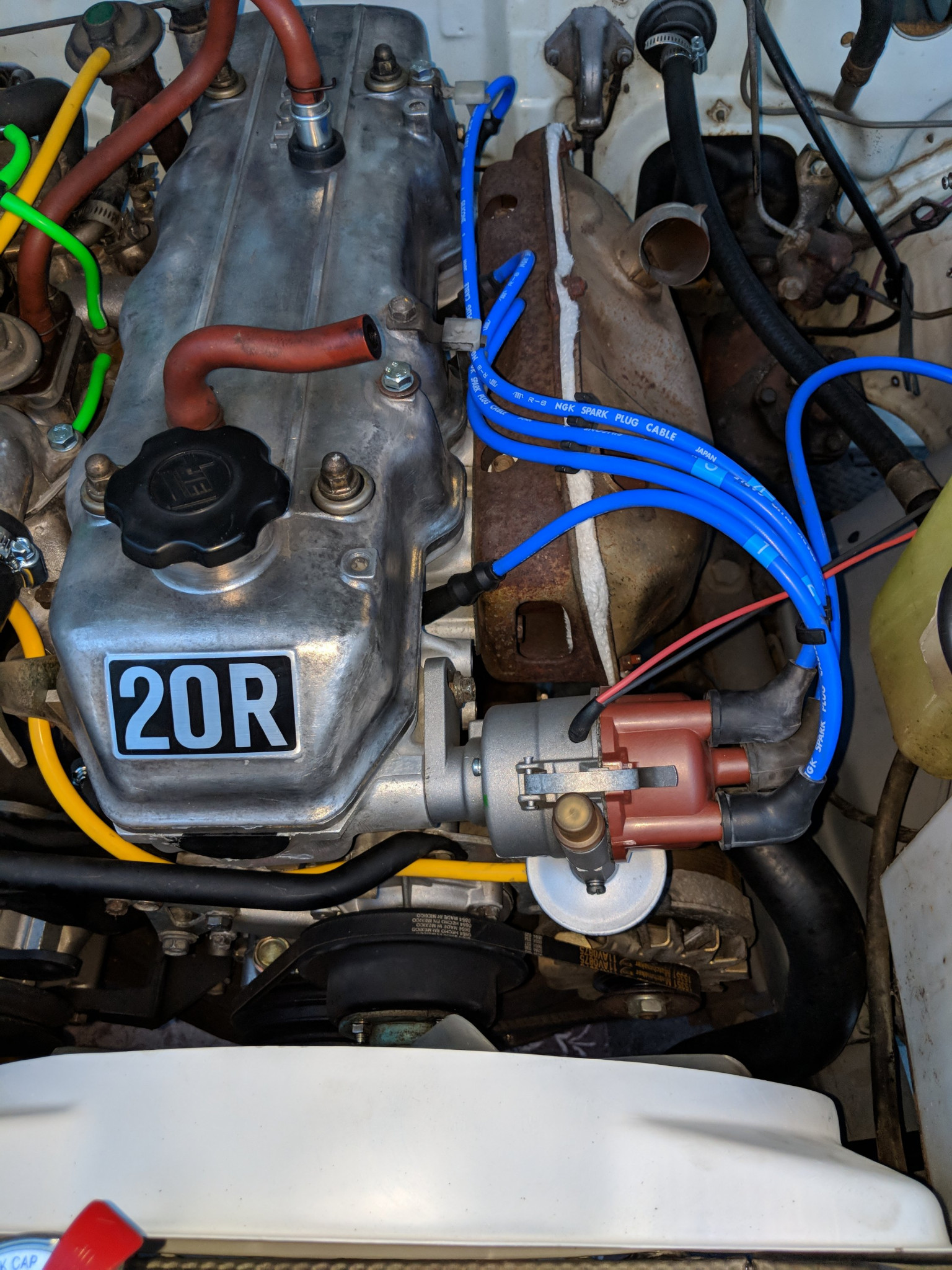

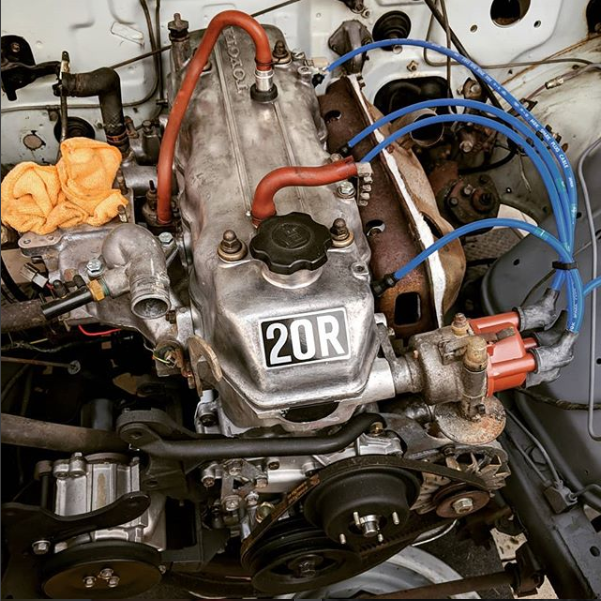

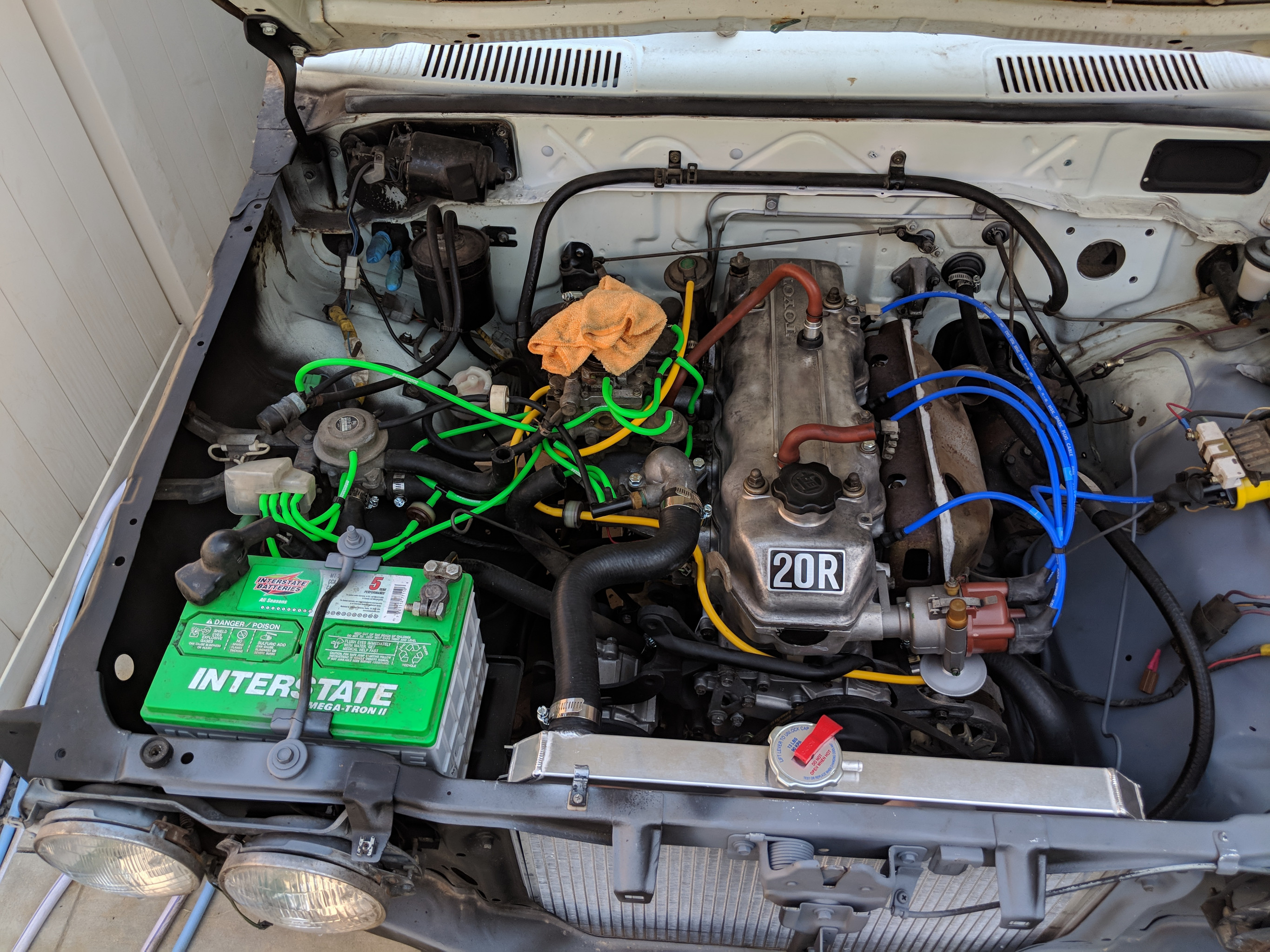

Worked on outlining the changes i need to make to the ignition. This includes the replacement of points to Pertronix electronic ignition. Got a replacement Accell coil, and confirmed that its resistance/voltage allow for the removal of the white resistor. It supports higher voltage, like the flamethrower coils. Otherwise the voltage is too low for […]

We reinstalled the gas tank and got a gallon or two of gas in the tank. We then did a compression test, and confirmed compression stroke /w top dead center on the first piston. Reinstalled all new Silicone vacuum lines and Placed the timing angle at 13* (high altitude) and turned the 20R engine over! […]

The rear door seal has been replaced on the outer side the inner door needs to be completely pulled out of the Chinook looks like welds need to be broken. Replaced all the old rubber vacuum lines with silicone ones, color-coded some of the important ones yellow. De-rusted and repainted the fan guard, as well […]

Looking At replacing some aged and weathered parts. Water entry and regulator need to be replaced due to 30+ years of sun damage. Replacing hand pump sink with something more modern/electric. Hot side can be plugged into the regulator and cold side can be electric pump facing. May 3D print a separate base for the […]

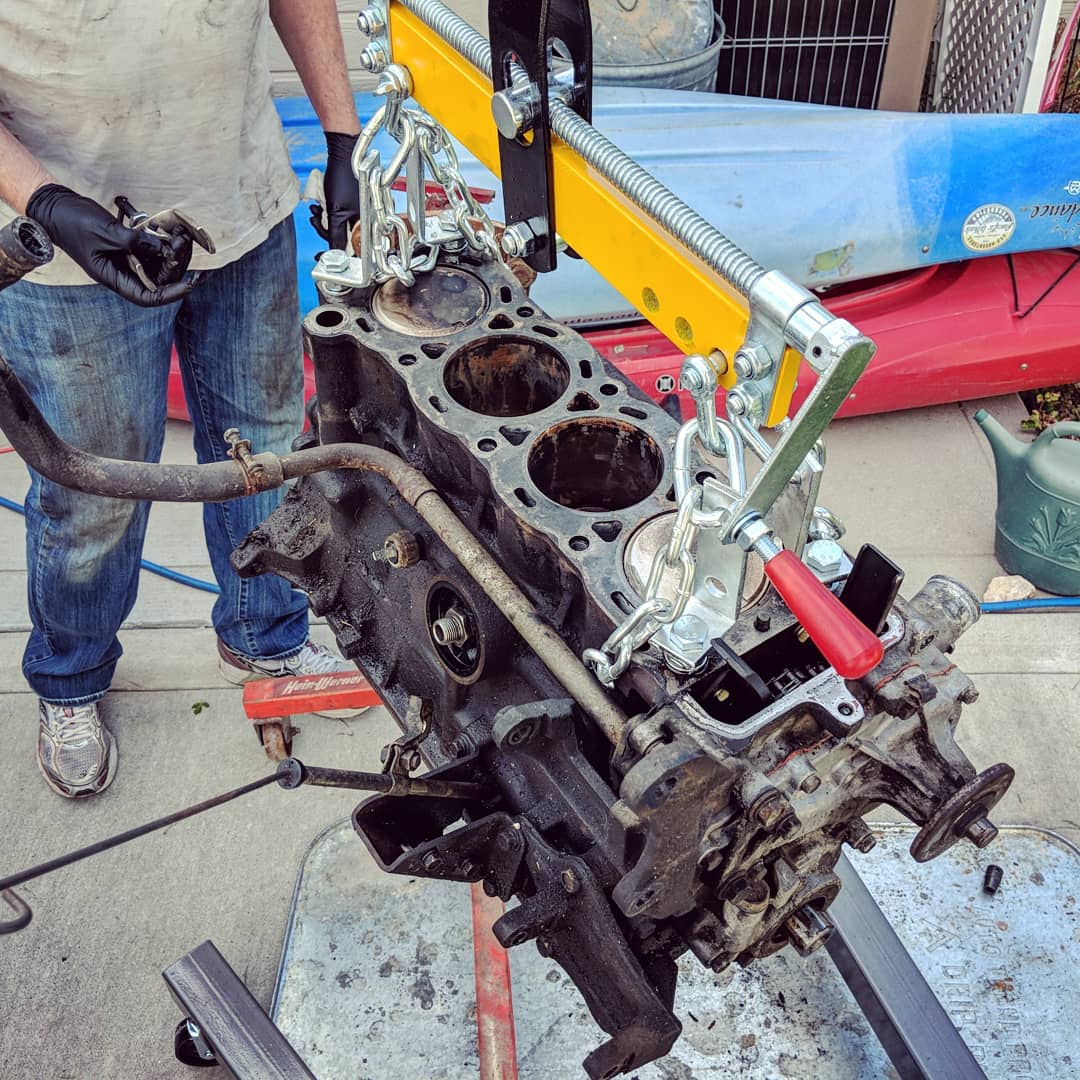

The engine is back from being bored, pistons and rings in hand. Identifying work that needs to be done on the transmission. Assembling the low and top end of the engine. Cleanup of bell housing and oil pan. Clutch kit is on order.

With a cheap harbor freight hoist the 20r engine and R43 transmission have been pulled. The block crank and head will be taken to a local shop to get bored honed and rebuilt. Cylinders didn’t look to bad for 80k miles. Since the Chinook had a blown head gasket, my guess is that it overheated […]