Hey Everyone, I just got setup with a star link referral program. Use the link below to get a free month of star link when setting up your account. Click Here for a free month of Starlink internet

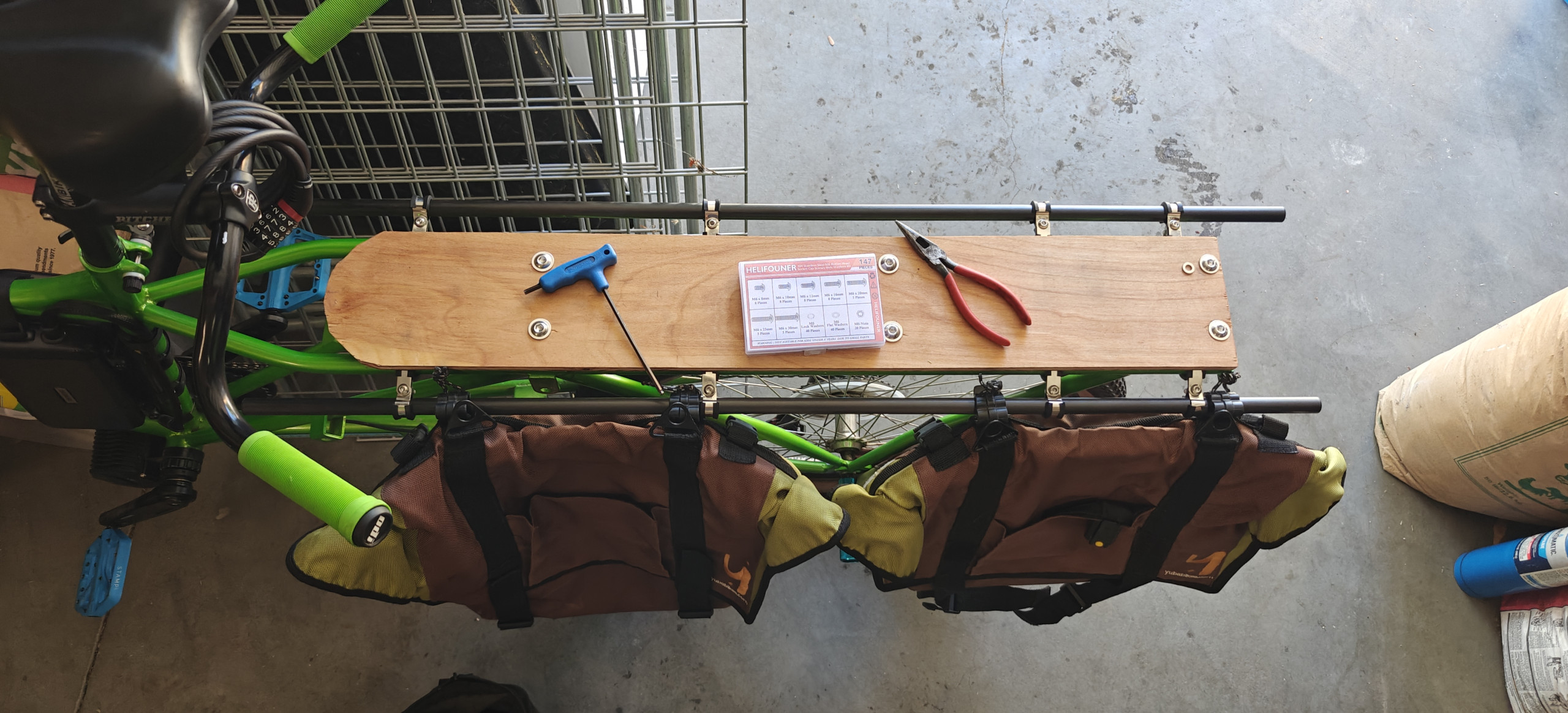

With the hard part out of the way Project Rwanda Coffee Bike – CYC Photon Conversion (Part 1), the remaining pieces include pannier rails, a new rear deck, and figuring out a better seat pad for the bike. I started out with ordering 2 x 16mm x 1000mm carbon fiber tubes, some rubber endcaps, and […]

Took a weekend drive to bend Oregon to take a look at and buy this 8 Speed Cargo bike for $200. The product of a Tom Richie project that collaborated with coffee farmers in Rwanda. You can read more about these bikes here. I ended up stripping and removing the wood decks, and taking a […]

These power supplies have been around for a while, these two came out of a Pure Storage array at work after a SAS to NVME upgrade project. The power supplies themselves are dedicated 12V Rails, and have documentation. The challenge was finding the correct datasheet and understanding the pinout. The Top of the PSU on […]

Started the teardown of the crash/burn crowdfunded sous vide cooker by cook Mellow. The site is offline, the service and app are offline and it is an IOT Brick. A Simple teardown reveals the following “MC_ECU_V05” custom pcb running electric imp silicon and software with built in wifi: Electric Imp Secure IoT Connectivity Platform they […]

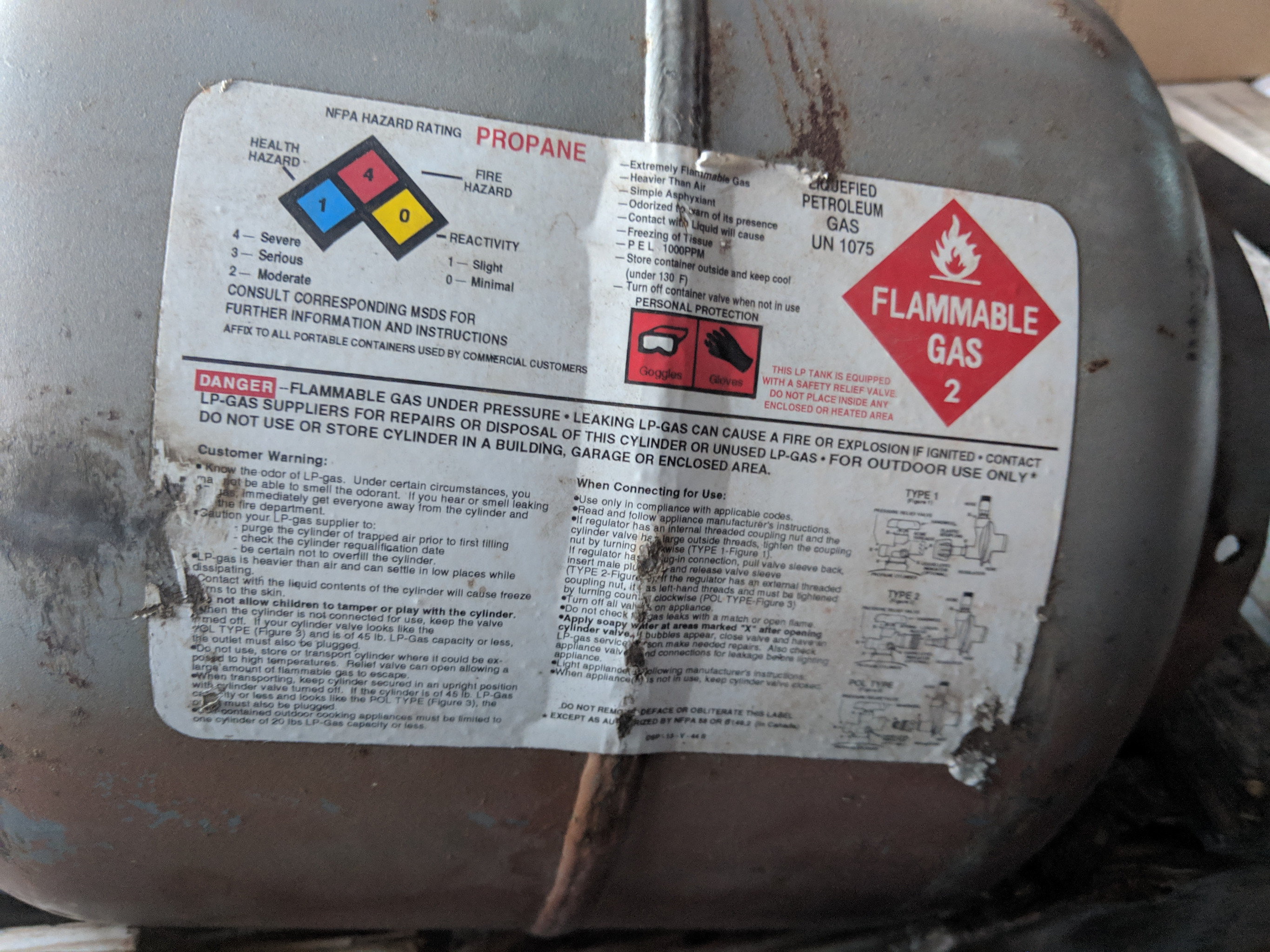

It turns out the tank i had no matter what could not be re-certified. It was old, rusty and on the inside had some rust. So i found two local tanks on craigslist that fit the description. Made in 1998′ there were a few differences. Notably the fact the propane valve is 90* upward versus […]

The Manchester 20lb horizontal tanks are expensive in the sense that they are highly sought after. They are technically exempt since they were built before 1998 and are non OPD valve retrofittable. The valve-cores are replaceable, and the surface rust is easy to clean and prepare a new paint-job. I was hesitant and looked at […]

Got the Chinook over to the DMV and registered! Still waiting on front brakes to show up. Still outlining the work that needs to be done on the door frame and sealing/re-framing the roof. The sink faucet needs to still be installed, and a base 3D printed to replace where the hand pump faucet was.

Replaced rear wheel cylinders and brake pads including hardware. Ran into an issue where the passenger side rear wheel for some reason was a millimeter or so off and had to lightly file down for the replacement part to fit. The original wheel cylinders look way cooler since they have to old school Toyota logo […]

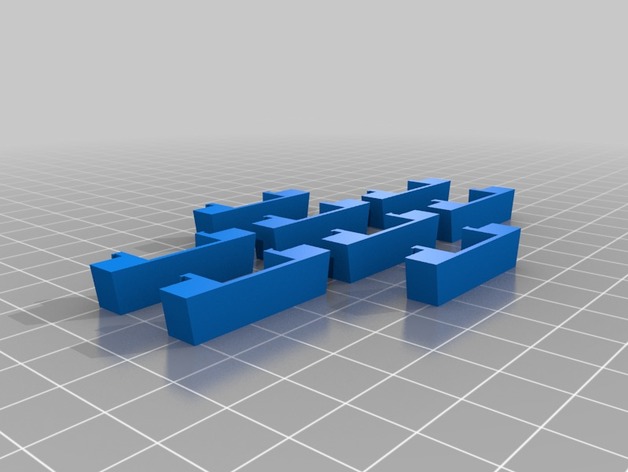

I was able to re-create the flimsy sun damaged weep hole vents that were originally on my 1977 Toyota Chinook. All 8 print in about 2 hours /w 1.75mm ABS plastic filament and .1mm layer height on my Reprap Prusa i3. I’ve published the part on Youmagine